Designing, engineering, manufacturing and erecting distinctive home extensions in Ireland and now the UK for over 30 years. Our manufacturing facility employs the latest in pre-cast concrete form engineering, capable of casting curved moulds with glazing openings both inverse and linear. In the case of our timber-engineering department, we can cater for all manner of geometry. This has proven particularly relevant to the UK market in creating imaginary and contemporary roofing forms for our clients.

Limited only by imagination, our innovative process can engineer and install to your own pre-existing plans or our newly developed ones. What’s more, our system can replicate any structural designs that may have caught your eye.

A service designed primarily, but not exclusively, for planning exempt customers, our process employs the very latest in off-site home extending technology both hard and soft,

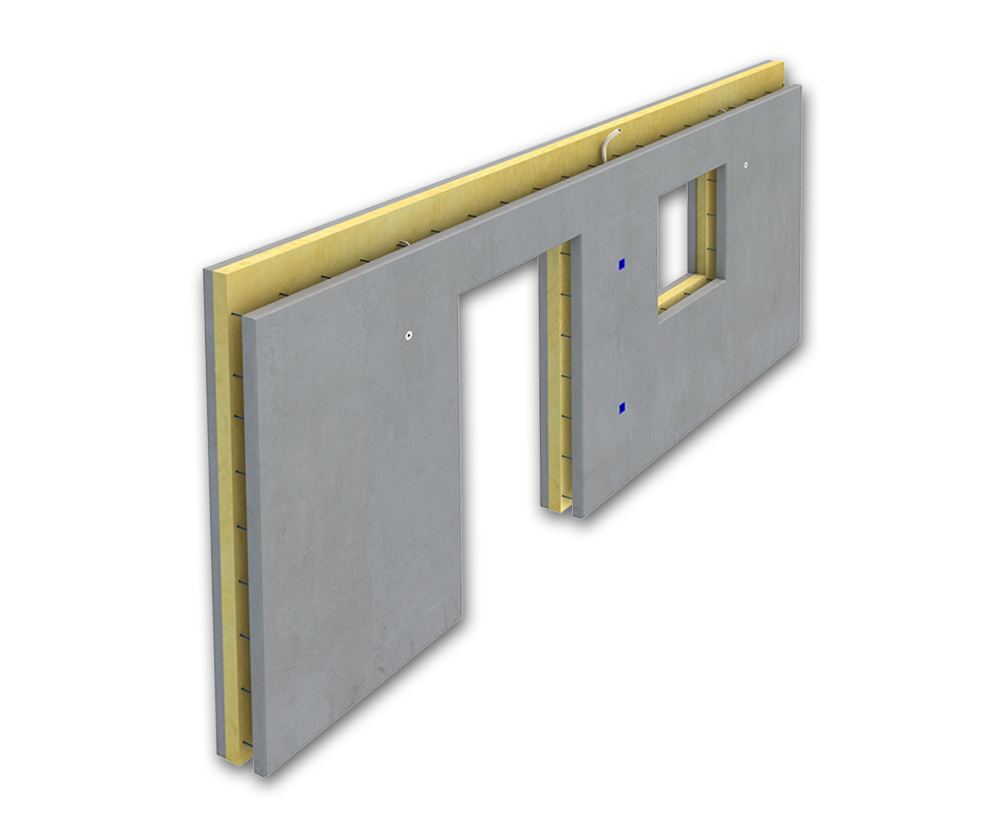

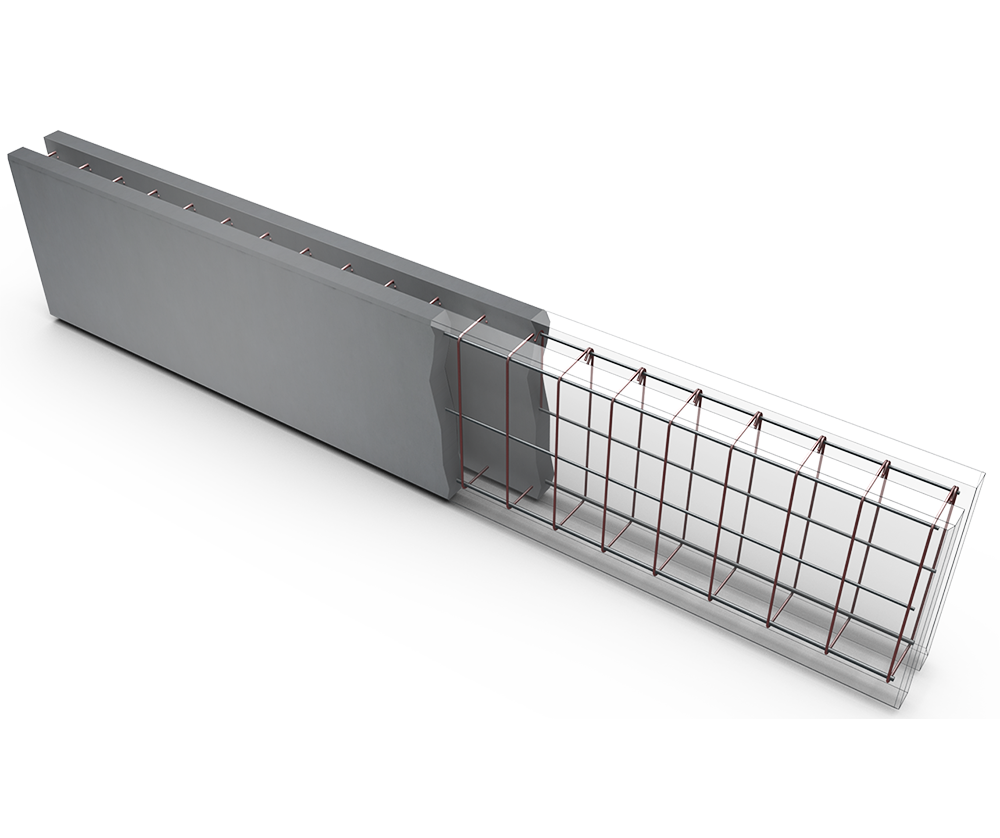

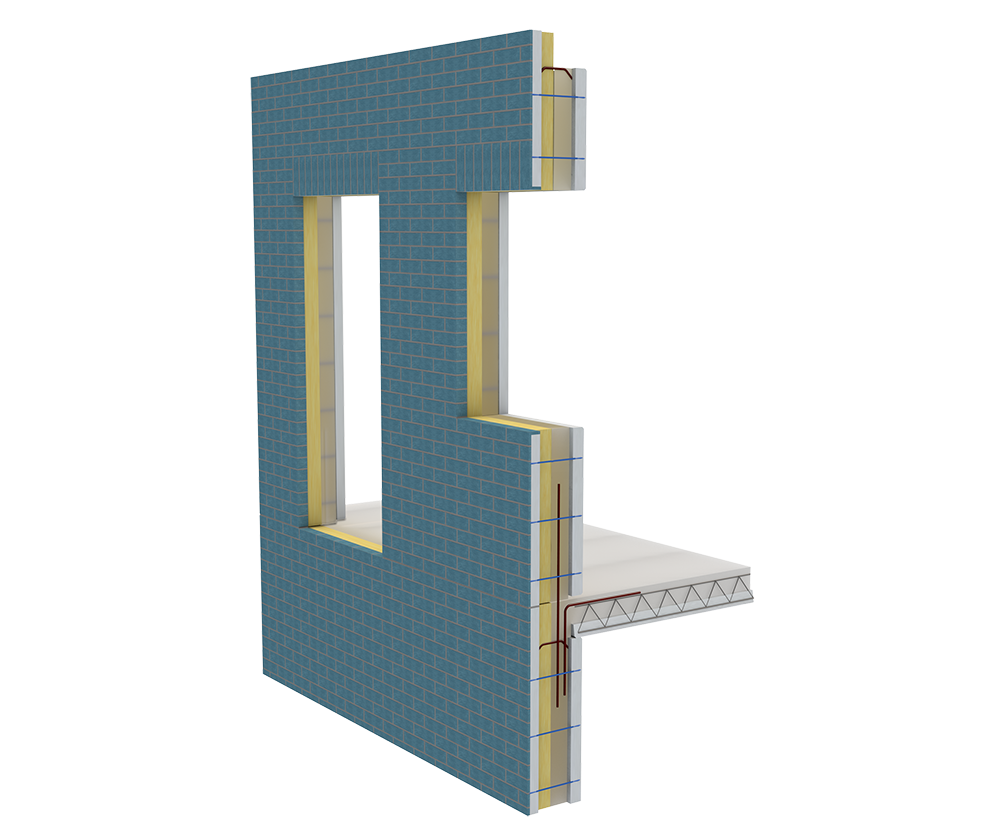

Most modern extensions require significant structural steel for true open plan living with regard to the removal of the structural rear wall but also to be current building regulation compliant, all new external walls must be twin-leaf with an insulated clear cavity enveloping the structural envelope. However these type of walls are not suited or designed for clear span glazing weight transfers. This has particular regard for any new walls with large windows and door openings – hence most modern designs now need the entire super structure in steel. However with steel being a highly regulated industry, it makes sense to begin that process prior to project commencement and not half way through the on-site linear building process adding weeks to the build at the worst possible time for you and your family as most likely at that point of the traditional on-site build, you will have little or very reduced services with no back wall propped up on acrows as the steel only then begins its regulatory design and manufacturing process as is market norms within the sector conforming with 2014 CE marking engineering and building regulations.