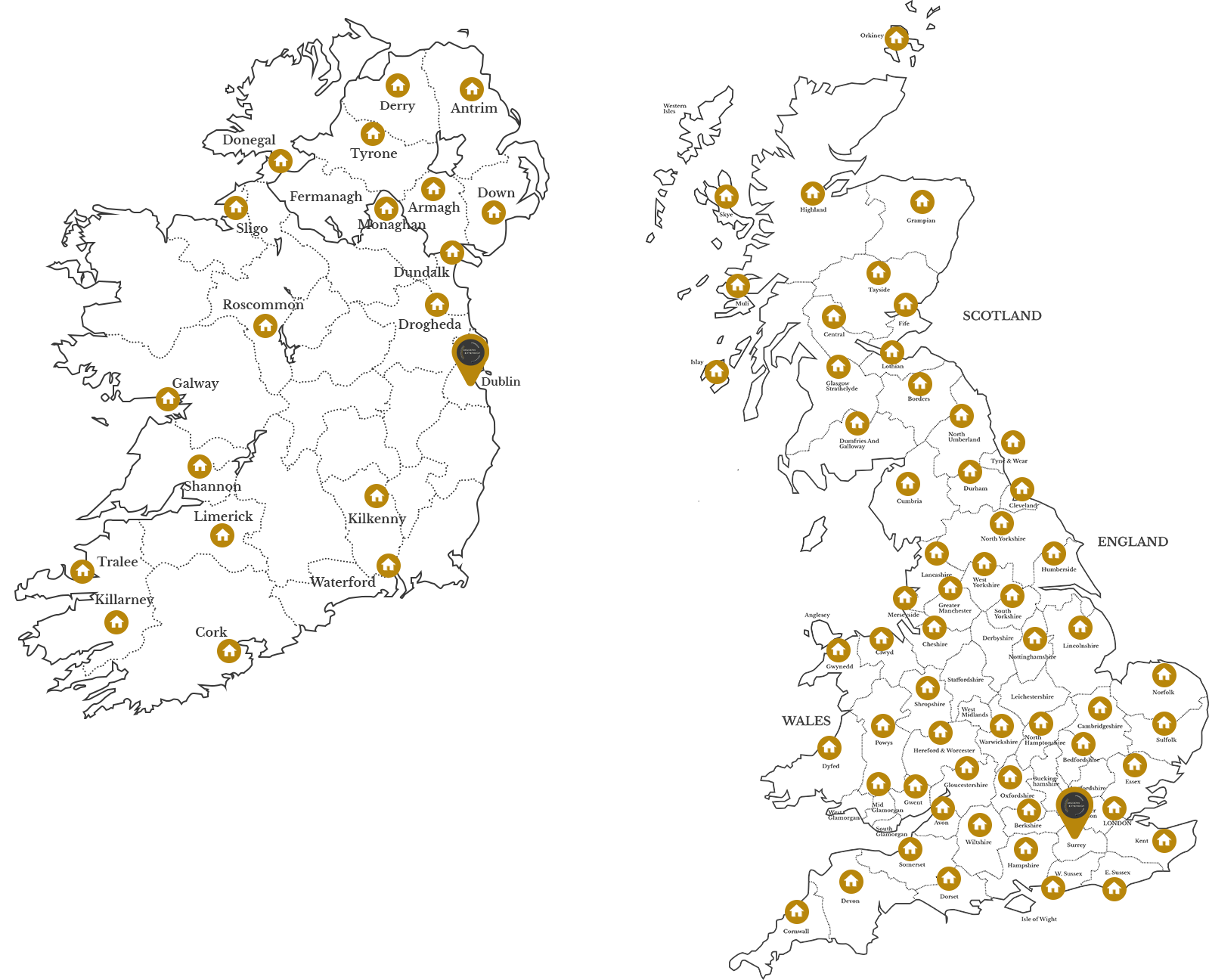

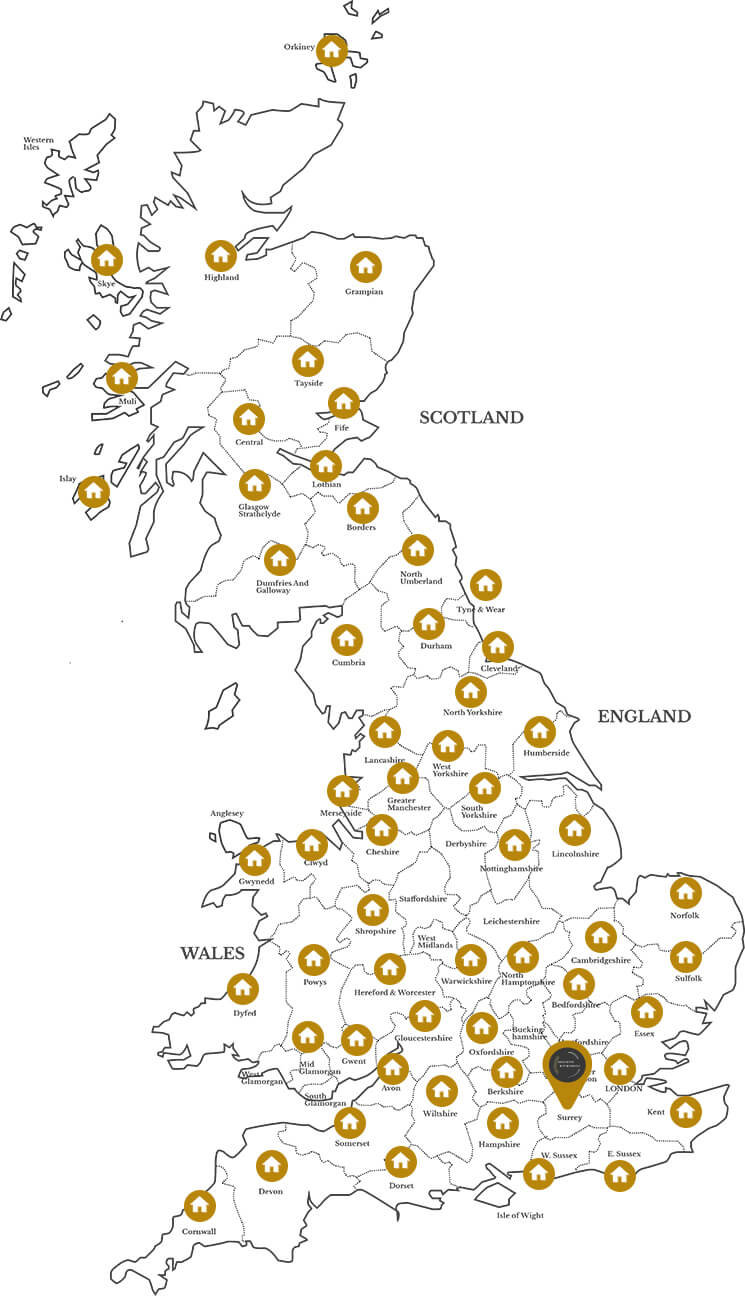

So much so we have written an app, but not just any app – a seductively simple immersive one, capable of generating over 13,000 relevant contemporary designs to the pre-existing layouts of the Irish & UK housing markets, not just in 2D or 3D/AR app but in holographic, truly immersive MR. Modern Extension has teamed up with some of the most talented MR app developers in the country. The Modern Extension factory app powered in the field by the cloud is a sector first and is a fine example of how edge-based cloud computing is set to transform home extending design and delivery Click the link and discover a whole new way to interact with CAD – Computer Aided Design

A more cost effective and cohesive system than engaging an architect, engineer, quantity surveyor and builder separately, digitising our projects allows for seamless off-site collaboration and quick decision making, with a network of previous similar projects already digitised for cross-referencing removing the traditional physical fragmentation between off-site design professionals and onsite trade professionals.

The very latest in twin leaf wall engineering with up to 150mm clear insulated cavity encompassing the entire structural envelope ensuring no cold bridging from inner to outer wall leaf, coupled with the strength of a pre-engineered steel reinforced mass concrete mould, all bolted to a pre-engineered steel super structure. There simply is no on-site construction system within the residential construction sector that comes close to it.

Prior to project commencement, design plans with internal layouts regarding mechanical, electrical, stud partitions, w/c utility and kitchen. External elevations side and rear, roofing options developed flat, pitched or combination with square metre to floor area lighting ratios. On-site drainage surveys producing effective drainage plans for the management of foul, sewer and surface water management.

On-site survey and data capture exported into AutoCAD/Tekia for advanced 3D structural modelling, allowing for all structural components to be ordered and manufactured from within the CAD file with digitised tolerances built in from design stage ensuring the tightest possible fit for windows and doors. and all other structural constituent parts.

That push span and glazing boundaries, all designed, engineered, signed-off and fabricated prior to project commencement and not halfway through the project as is traditional linear building norms, eliminating persistent long frustrating delays with no on-site forward progress conforming with steel structural requirements.

Builders - Boost your Productivity - we supply and erect structural kits to the trade. We also cater for the self-build trade with full consultancy services on (all) aspects of your project - with remote assist, diagrams, drawings, engineering, building regulations, advice, problem solving - sent straight to your phone, in the field, in real time. Safe in the knowledge that a professional is always on hand as you meet and overcome the many daily challenges your project will undoubtedly present.

![]() Our engineering and manufacturing is well suited to pre-existing timber frame house construction.

Our engineering and manufacturing is well suited to pre-existing timber frame house construction.

Genuine discount invoicing applied to all finishing specs regarding flooring, tiling, doorsets, sanitary wear,kitchens from leading suppliers in the sector.Our engineering and manufacturing is well suited to pre-existing timber frame house construction.

A challenge to fundamentally reorganise the traditional business model to one that is forward looking and sustainable.

We can’t have infinite growth on a finite planet. A carbon neutral commitment by 2030 to include all factory processes and procedures extending to the electrification of our transport fleet.

We are all aware of the now cascading problems the environment faces. We at Modern Extension believe businesses must face up to the challenges as the innovators and wealth creators of the defining problem of our age – we broke it, we own it. That is why we are launching The Taking Pledge! of all fossil fuel burning from our entire manufacturing and distribution chain.

With all structural components pre designed, ordered and manufactured prior to project commencement, i.e. steel, walls, roof, windows and doors, roof lights and only being shipped once to tie in with the on-site groundcrew, the carbon footprint is massively reduced with most of the noise and heavy construction work happening atthe factory and not back and forth to your home.

Extending your home shouldn’t mean turning it into an open ended disordered building site for months on end for lack of joined up thinking, perpetuated by the intellectual glass ceiling imposed on the sector. The advancement of commonplace technologies has made the long prevailing system look very outdated, whose time has possibly come and gone. It could be argued to build anything of any significance in the 2020s is a failure of joined up modern technological planning.